About Us

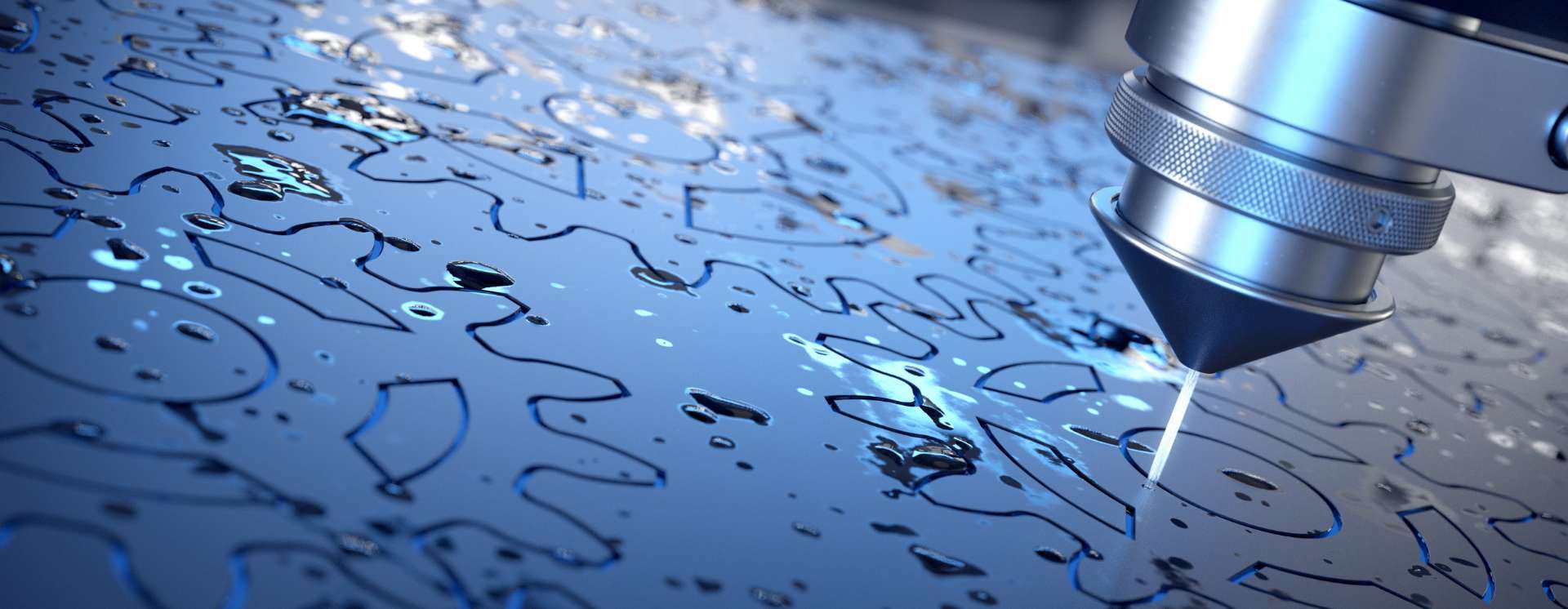

About Remcon Waterjet

Remcon Waterjet formed in Ohio in 1982 to serve various industrial enterprises. We have been providing waterjet cutting services since 1986.

Our in-house capabilities include abrasive jet cutting of metals, glass, stone, and composites and pure waterjet cutting of foams, plastics, rubber, and composites.

In the spring of 1995, Remcon consolidated operations and moved into a new building in Akron, Ohio. Our cutting service capacity has been doubled and efficiencies have improved. We also doubled our ability to rebuild and integrate systems in a separate bay.

We currently have three cutting machines in production.

Our cutting power is generated by four dual/redundant Intensifiers rated at 60,000 psi with a total output of 8 gpm. We can cut with up to eight heads at a time. The cutting power generates a very fine stream of water travelling at two to three times the speed of sound (faster than many bullets). The stream is smaller than a pin but a jet 1/70th of an inch in diameter packs nearly 50 horsepower.

For metal cutting, garnet abrasive is added after the jet is formed to permit routine cutting up to 8” thick stainless steel. The size of the jet itself increases but is still less than 1/16″. Our maximum cut width is .060″ to .080″

The major advantages of waterjet cutting are cut quality, the lack of heat in the cutting process, the quality of the cut itself, and the ease of applying modern CAD/CAM and shape generation methods.

Equipment (In-House):

- Intensifier pumps – 325HP + 100HP backup

- CNC Cutting Machines (3) – 6′ x 12′, 4′ x 6′, 28″ x 56″

- Abrasive Cutting – 6 heads (.014)

- Plain Water – 12 heads

- CAD/CAM, AutoCAD DXF, DWG, SigmaNEST

Parts (Stocking):

- Intensifiers, accumulators, filters (Flow, I-R, KMT, WSI)

- Hydraulic Pumps – new & re-built (Rexroth A10V)

- High Pressure tubing and fittings, 60K PSI, 100K PSI

- Power matched grit, nozzles, heads

- Orifices .004-.022″

- Long Life Nozzles (Roctec) .025″ – .090″ ~ 70-250 hrs.