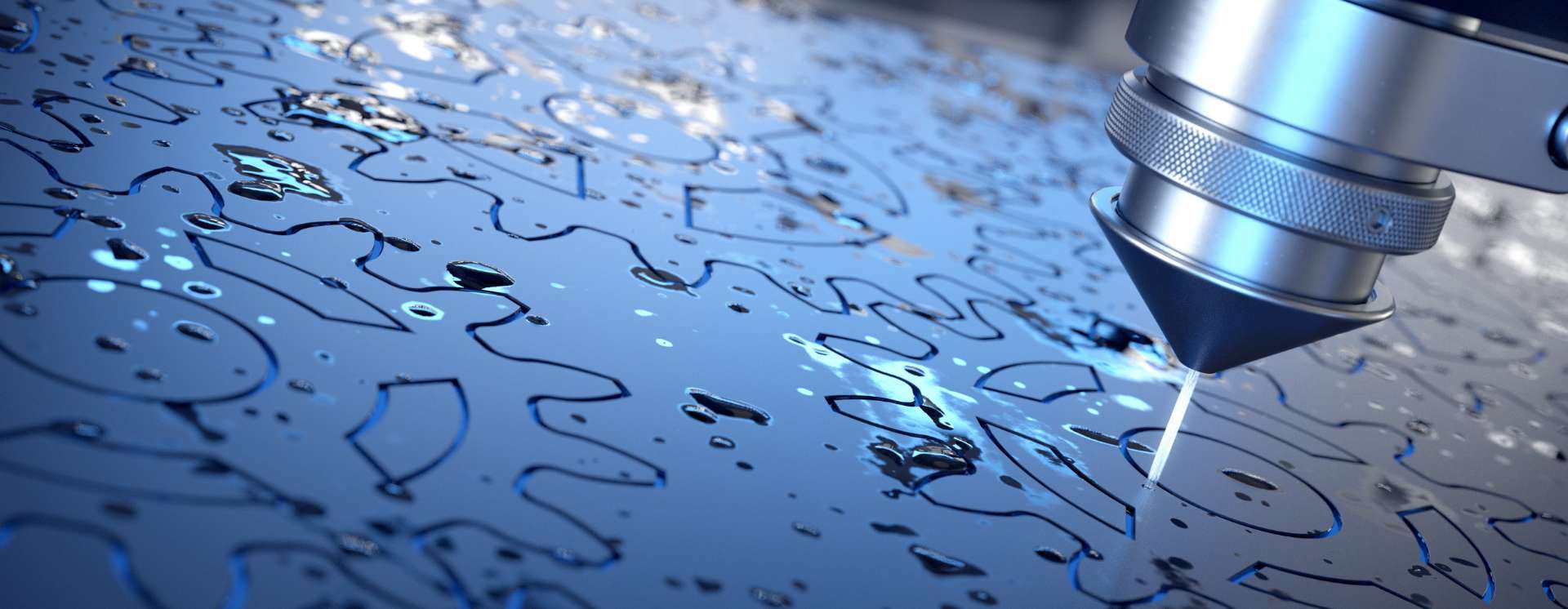

Waterjet Cutting

& Equipment

What We Do

Remcon remanufactures waterjets and cuts parts using the same process. We have been providing waterjet cutting services since 1986. Our in-house capabilities include abrasive jet cutting of metals, glass, stone and composites, and pure waterjet cutting of foams, plastics, rubber and composites.

The cutting power is generated by a very fine stream of water traveling at two to three times the speed of sound (faster than many bullets). The stream is smaller than a pin but a jet 1/70th of an inch in diameter packs nearly 50 horsepower.

The major advantages of waterjet cutting are the lack of heat in the cutting process, the quality of the cut itself and the ease of applying modern CAD/CAM and shape generation methods.

Why Use Waterjet Cutting?

There is no heat affected zone:

- No microcracking.

- Often eliminates deburring, grinding.

- Parts do not distort.

- We can cut heat treated material.

Material utilization improves:

- The jet profiles vs making chips.

- Drops can be salvaged.

- Nesting and line-to-line cutting work – no heat affected zone.

Secondary machining costs are lower:

- Cutter life is longer and feeds higher.

- Net shapes generated.

- Produces smooth precise edges with minimal material distortion.